Cryogenic Grinders at Rs 2500000/unit(s) - IndiaMART

₹ 25 Lakh/ Unit (s) Get Latest Price Cryogenic grinding is a process of mixing Liquid Nitrogen with a spice to lower the temperature up to -190

More

Key issues and challenges in spice grinding - ScienceDirect

2021年12月1日 Grinding methods, liquid nitrogen, and moisture content were major critical factors. ... India is the top spice producing, consuming, ... For developing a spice

More

Axtel Industries Limited

Spices Grinding Post-cleaning, the spices are ground using either of the two technologies – Low Temperature Grinding or Cryogenic Grinding. Cold air is utilized in the previous

More

Mix Spices Processing Plant manufacturer India - Rieco

Cryogenic Grinding Technology: Our Cryogenic grinding technology enables to grind high VO spices in sub-zero temperature wherein the seeds spices are blanketed in liquid

More

Commercial Spice Grinder Machine - Pulplizer Grinder

Semi-Automatic Commercial Spice Grinder Machine, Blower Pulverizer, 20 - 2000 kg/Hr ₹ 10,000 Get Latest Price Capacity: 20 - 2000 kg/Hr Usage/Application: grinding spices, masala, chilli, turmeric, coriander,

More

Cryogenic Spice Grinding Plant, Single Phase - IndiaMART

Cyclone Rotary Airlock Valve (RAV) Silo (if required) We also provide cryogenic attachment to our grinding machine. The cryogenic technique involves the exposure of the raw material to liquid nitrogen at -150

More

Cryogenic spice grinding: A boon to spice processing

Using liquid nitrogen or liquid air as the cryogen, all of thermo-sensitive spices can be ground below their brittle point temperature. The color and other properties of the

More

Cryogenic spice grinding: A boon to spice processing

2013年10月1日 Grinding Cryogenic spice grinding: A boon to spice processing October 2013 Conference: 2nd International Conference and Exhibition on Food Technology, Bioprocess Cell Culture Authors:...

More

The 8 Best Spice Grinders of 2023 Tested by The Spruce

2023年2月1日 Out of all the best spice grinders on the list, the Kuhn Rikon may also be the easiest option to clean. Instead of hand washing or putting it through the dishwasher, all you have to do is add some coarse salt to the

More

Key issues and challenges in spice grinding - ScienceDirect

2021年12月1日 Cryogenic grinding ( Fig. 1), a method in which liquid nitrogen (boiling point of −195.6 °C) is being used to pre-freeze the material before grinding (Balasubramanian et al., 2012) and removing heat during grinding, is the advanced and effective method to maintain the quality of spices during grinding ( Saxena et al., 2015 ).

More

Axtel Industries Limited

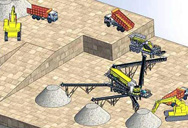

Spices Grinding Post-cleaning, the spices are ground using either of the two technologies – Low Temperature Grinding or Cryogenic Grinding. Cold air is utilized in the previous case, while liquid nitrogen is deployed in the latter case, so as to keep the temperature in the grinding chamber as well as across the processing system within limits.

More

Automatic Cryogenic Grinding System, 20 HP, Three

₹ 25 Lakh Get Latest Price Cryogenic grinding is a process of mixing Liquid Nitrogen with a spice to lower the temperature up to -190 degrees C, then grinding the super-cooled product. This type of grinding system

More

Mix Spices Processing Plant manufacturer India - Rieco

Cryogenic Grinding Technology: Our Cryogenic grinding technology enables to grind high VO spices in sub-zero temperature wherein the seeds spices are blanketed in liquid Nitrogen and then grounded further to the required fineness. This helps to retain the essential volatile oil, aroma color. Sifting Process:

More

Spice Grinding Machines - Turmeric Impact Pulverizer

Dimension. 4 (L)*2 (W)*4 (H) Machine Capacity. 20-30 Kg/hour. Main Motor. 3HP. Proveg Engineering Is The Leading Manufacturer For Spice, Turmeri, Besna Processing Plant And Machineries. The Company Is In This Business Since Last 15 Years And Sucessfully Installed Many Plant In Pan India. The Company Is Continuously Upgrading The

More

CRYOGENIC GRINDING OF SPICE

CRYOGENIC GRINDING OF SPICE 1.INTRODUCTION: Spices are very important and essential for adding and enhancing flavor, taste and scent in preparation of food. They are also useful in preparation of certain medicine. India is the largest producer, consumer and exporter of spices Andhra ... This technology uses liquid nitrogen to control the ...

More

The 8 Best Spice Grinders of 2023 Tested by The

2023年2月1日 If you need a spice grinder that can handle larger quantities of spices for batch cooking or meal prepping, the Cuisinart Spice and Nut Grinder is one of the largest and most powerful options out

More

(PDF) Performance Evaluation of Different Types of

2015年6月1日 The pin mill performed best as a single machine in terms of particle size of ground product among two types of spice processing machinery. However, the machinery combination of plate mill gave...

More

(PDF) Key issues and challenges in spice grinding - ResearchGate

2021年11月1日 Several techniques and methods are being applied in the spice grinding process like conventional grinding (hammer, plate, pin mill), superfine grinding (ball, jet, roller mill), improved...

More

Spices Manufacturing Process - Indpro

2022年2月21日 Grinding the spices is done using either low temperature or cryogenic methods. Using cold air in the first situation and liquid nitrogen in the second, heat is controlled within safe limits in the grinding chamber and throughout the milling system. In this way, the final spice powders are more fragrant, colored, and flavourful.

More

Spice Grinding Machine - TradeIndia

Spice grinding machines are essential equipment in the food processing industry. These machines grind various spices and herbs to create flavorful blends for cooking. Find top manufacturers and suppliers of spice grinding machines on Tradeindia, offering a range of models to suit different needs and budgets.

More

Spices, Roots, Medicinal herbs Teas Hosokawa Alpine

Heat is generated during the grinding process, which has two consequences: Firstly, the essential oils evaporate, and secondly, the heat-sensitive fats melt. In the worst case, this can cause the grinding elements to clog up and the entire mill to block and stall. This is prevented by cryogenic grinding with mainly liquid nitrogen as a cooling ...

More

Liquid Nitrogen Grinding Machine - Alibaba

Find liquid nitrogen grinding machine types and parts from wholesalers in China. Shop for grinding equipment and parts at Alibaba and find a variety at competitive prices. ... Liquid Nitrogen Spice Grinding Machines With Cooling System $2,700.00. Min Order: 1 set. CN Supplier . 15 yrs. 5.0 /5 13 reviews "good supplier" Contact Supplier.

More

1 SPICES CRYO-GRINDING UNIT - MP AGRO

technology uses liquid nitrogen to control the grinding chamber temperature, the result of which is reduction in loss of volatile essential oils in the spices and higher production rate. 1.3 Raw Material Availability Total spice production in the state is 3.15 lakh MT. The area and production with the

More

Mix Spices Processing Plant manufacturer India - Rieco

Cryogenic Grinding Technology: Our Cryogenic grinding technology enables to grind high VO spices in sub-zero temperature wherein the seeds spices are blanketed in liquid Nitrogen and then grounded further to the required fineness. This helps to retain the essential volatile oil, aroma color. Sifting Process:

More

PREMIER SPICE GRINDER KM-521 (WET DRY MIXER GRINDER) CODE-082001

The stylish Premier 2-in-1 Coffee Spice Grinder 350W with 400 ml capacity can be used for both wet dry grinding. This all-purpose grinder is a must-have for any kitchen Removable polished Stainless Steel cup with Stainless Steel blades for coffee beans, spices, garlic, ginger, chilies, and vegetables.

More

Spices, Roots, Medicinal herbs Teas Hosokawa Alpine

The Ultraplex UPZ fine impact mill is known as the universal spice mill, due to its flexibly of using different grinding tools and adjustable rotor speeds. It is the mill of choice for root spices, seeds, fruit skins and husks with a high ash content and extremely hard seed pods such as rose hips.

More

Spice Grinding Machines - Turmeric Impact Pulverizer

Dimension. 4 (L)*2 (W)*4 (H) Machine Capacity. 20-30 Kg/hour. Main Motor. 3HP. Proveg Engineering Is The Leading Manufacturer For Spice, Turmeri, Besna Processing Plant And Machineries. The Company Is In This Business Since Last 15 Years And Sucessfully Installed Many Plant In Pan India. The Company Is Continuously Upgrading The

More

Cryomill - the perfect mill for cryogenic grinding - RETSCH

The CryoMill is a cryogenic grinder designed with user safety in mind. The liquid nitrogen flows through the closed system and the user never comes into direct contact with LN 2 which ensures a high degree of operational safety. The automatic cooling system guarantees that the grinding process is not started before the sample is thoroughly cooled.

More

Spice Grinding Machine - TradeIndia

Spice grinding machines are essential equipment in the food processing industry. These machines grind various spices and herbs to create flavorful blends for cooking. Find top manufacturers and suppliers of spice grinding machines on Tradeindia, offering a range of models to suit different needs and budgets.

More

Spices Manufacturing Process - Indpro

2022年2月21日 Grinding the spices is done using either low temperature or cryogenic methods. Using cold air in the first situation and liquid nitrogen in the second, heat is controlled within safe limits in the grinding chamber and throughout the milling system. In this way, the final spice powders are more fragrant, colored, and flavourful.

More

CRYOGENIC GRINDING OF SPICE

CRYOGENIC GRINDING OF SPICE 1.INTRODUCTION: Spices are very important and essential for adding and enhancing flavor, taste and scent in preparation of food. They are also useful in preparation of certain medicine. India is the largest producer, consumer and exporter of spices Andhra ... This technology uses liquid nitrogen to control the ...

More

Liquid Nitrogen Spice Grinding Machines With Cooling System

Liquid Nitrogen Spice Grinding Machines With Cooling System , Find Complete Details about Liquid Nitrogen Spice Grinding Machines With Cooling System,Grinding Machine,Grinding System,Spice Grinding Machine from Grinding Equipment Supplier or Manufacturer-Jiangyin Baoli Machinery Manufacturing Co., Ltd.

More

Liquid Nitrogen Grinding Machine - Alibaba

Find liquid nitrogen grinding machine types and parts from wholesalers in China. Shop for grinding equipment and parts at Alibaba and find a variety at competitive prices. ... Liquid Nitrogen Spice Grinding Machines With Cooling System $2,700.00. Min Order: 1 set. CN Supplier . 15 yrs. 5.0 /5 13 reviews "good supplier" Contact Supplier.

More

Cryo Milling Material Milling AVEKA

Cryogenic milling, or cryo-milling, is the process of using liquid nitrogen to lower the temperate of the material and/or the milling process. AVEKA ‘s cryogenic hammer mills can typically reduce the particle size from small pellets down to the 100s of microns. Cryo-milling can be used for:

More

CRYOGENIC GRINDING: A PHYSICAL TECHNIQUE TO RETAIN

herbs and spices are frozen with liquid nitrogen as they are being ground. This process does not damage or alter the chemical composition of the plant or seeds in any way. Normal grinding processes which do not use a cooling system can reach up to 200 oF. These high temperature can reduce volatile components and heat sensitive constituents in

More

Cryogenic Equipment at Best Price in India - IndiaMART

CRYOGENIC GRINDER ₹ 39.5 Lakh/ Piece Get Latest Price Material: Stainless Steel 304 Production Capacity: Min 20 kg to Max 500 Kg Food samples grinding suitable for all spices and other commodities Working temperature: 35°C to -195°C Refrigerant: liquid Nitrogen read more... KK Lifesciences Triplicane, Chennai TrustSEAL Verified Company

More

Cryogenics and its application with reference to spice grinding

Although there is a wide range of cryogens to produce the desired low temperature, generally liquid nitrogen (LN₂) is used in food grinding. The application of low temperature shows a promising pathway to produce higher quality end product with higher flavor and volatile oil retention.

More