Steady state inferential modeling of temperature and

2009年6月25日 Mill operational data obtained from an ESKOM power plant. Mill specifications: diameter = 4.692 m, length = 6.56 m, rotational speed ( N) = 75% of

More

(PDF) Control for pulverized fuel coal mill - ResearchGate

2015年10月1日 This paper focuses on the flow control of pulverized fuel (pf flow) of the coal mill. The control performance given by the conventional

More

What is Differential Pressure? - Mensor

Differential pressure, in general, is a measure of pressure where the reading and reference values are variable. Differential pressure is calculated by subtracting one of these values from the other. If Pipe A

More

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL

Mill differential pressure Water injection Mixture composition Product transport volume Grinding aid injection Composition of raw material Temperature after the mill Hot gas

More

Design of intelligent control system for Vertical Roller Mill

2011年7月1日 It was reported that only the mill input material feed rate has a decisive influence on the mill differential pressure (ΔP) while gas flow rate, grinding pressure,

More

How To Calculate Pressure Difference: What, How, Examples

Pressure is defined as the force per unit area. Pressure=Force/Area Where Force (F) is in Newton And Area (A) is in meter2 Therefore Pressure,p=F/A Newton/metre2 or Pascal.

More

What Is Differential Pressure? Donaldson Industrial Dust,

Differential pressure measured by a Photohelic Gauge or other electronic pressure drop indicators, can allow you to use low and high set points to control the cleaning cycle so it will start only when the differential

More

Dynamic classifiers: a fine way to help achieve lower emissions

2004年4月7日 Analysis of the results shows the mill pressure differential and the mill power consumption are a little higher with the dynamic classifier fitted. A significant

More

What is Differential Pressure? Variohm

Differential pressure is essentially the difference in pressure between two given points. It is a type of pressure measured within different industries using differential pressure sensors. There are 3 common types of

More

Modeling of energy consumption factors for an industrial ... - Nature

2022年5月9日 It was reported that only the mill input material feed rate has a decisive influence on the mill differential pressure (ΔP) while gas flow rate, grinding pressure, and classifier speed are ...

More

Coal mill model considering heat transfer effect on mass

2021年8月1日 For normal operation of coal mill, raw coal should meet following conditions: M a r is smaller than 18%; the hardgrove grind ability index, HGI, is between 40 and 80; the particle size of raw coal is smaller than 40 mm.

More

Operational parameters affecting the vertical roller mill

2017年4月1日 Mill differential pressure and dam ring height are constant. ⁎⁎ The kN/m 2 value is the pressure of the grinding roller applied onto the grinding table. The value accounts for the projected area of the roller onto the grinding table.

More

A unified thermo-mechanical model for coal mill operation

2015年11月1日 Empirical models are developed for mill differential pressure, and power consumption/current. Model parameters are estimated using Differential Evolution (DE) algorithm. The developed model is validated using actual data of the mill obtained from a 500 MW coal fired plant in India.

More

Steady state inferential modeling of temperature and pressure

2009年6月25日 Mill operational data obtained from an ESKOM power plant. Mill specifications: diameter = 4.692 m, length = 6.56 m, rotational speed ( N) = 75% of critical, mill filling ( J) = 15–20% of mill volume. 2.2. Industrial data Operational data was obtained from four ball mills at the Kendal power station in South Africa.

More

How To Calculate Pressure Difference: What, How, Examples

Pressure is defined as the force per unit area. Pressure=Force/Area Where Force (F) is in Newton And Area (A) is in meter2 Therefore Pressure,p=F/A Newton/metre2 or Pascal. Pressure increases as we move down from the liquid surface, the pressure is always greater for denser medium.

More

MillMaster—Technical - KIMA Process

pressure if the mill is under normal operation. Each time a limit is violated the fast decrease action will decrease the fresh feed and the roller pressure. inputs (actual values) mill vibration mill differential pressure main drive power main drive temperature torque signal roller pressure inputs (limits) mill vibration differential pressure

More

Modeling and Control of Coal Mill - ScienceDirect

2013年12月1日 The paper presents development and validation of coal mill model (including the action of classifier) to be used for improved coal mill control. The model is developed by using the mass and heat balance equations of the coal mill. Genetic Algorithm is used to estimate the unknown parameters that are used in the model validation.

More

Dynamic classifiers: a fine way to help achieve lower emissions

2004年4月7日 Analysis of the results shows the mill pressure differential and the mill power consumption are a little higher with the dynamic classifier fitted. A significant fraction of the increases measured is due to the harder coal being ground, 49 v 52 HGI, during the post conversion guarantee test at a nominal coal flow of 36 t/h.

More

Reduced Unit Capacity

The differential pressure across the bowl (“bowl DP”) is an indication of flow restrictions through the mill. Bowl differential is the combined draft loss across the vane wheel and the coal retained above the bowl. Bowl

More

Review of control and fault diagnosis methods applied to coal

2015年8月1日 (f) Mill differential pressure (mbar). (g) Mill current (A). As discussed above, the current control strategy for mills employed in most of the power plants is to divide the complex control process into several single loop PID controllers without considering interactions among these loops.

More

IOP 287 - Praveen Purshottaaim Parieek - Institute of Physics

Mill was in OEM operation for a long time to stabilize. 2.3.3 Method/Process Operation optimization or process optimization is a critical step responsible for efficient operation of Mill. It constitutes of optimization of operation parameters like

More

Coal Pulverizers - an overview ScienceDirect Topics

Calculate the average differential pressure for all the discharge pipes; xiii. Check that the variation between the calculated values of steps (xi) and (xii) is within ... The centralized system requires only one big mill and hence is more reliable, allowing for precise powder quality control with stable operation of equipment thus leading to ...

More

Melexis Pressure sensor ICs I Melexis

The MLX90824 is a packaged PCB-less, factory calibrated, absolute pressure sensor IC with a SENT output. It measures pressure spans from 1 to 4 bars. A pre-calibrated NTC thermistor input is available. Visit product page #Pressure sensor ICs #Pressure sensors MEMS Very low relative pressure sensor for automotive applications MLX90821

More

Modeling of energy consumption factors for an industrial ... - Nature

2022年5月9日 It was reported that only the mill input material feed rate has a decisive influence on the mill differential pressure (ΔP) while gas flow rate, grinding pressure, and classifier speed are ...

More

Operational parameters affecting the vertical roller mill

2017年4月1日 The control of the circulating load is achieved by adjusting the pressure drop over the mill comprising out of the gas flow and the solid loading inside the mill. Higher classifier rotor speed reduces the product particle size and hence increases the amount of internal grinding classifying circuits.

More

Steady state inferential modeling of temperature and pressure

2009年6月25日 Mill operational data obtained from an ESKOM power plant. Mill specifications: diameter = 4.692 m, length = 6.56 m, rotational speed ( N) = 75% of critical, mill filling ( J) = 15–20% of mill volume. 2.2. Industrial data Operational data was obtained from four ball mills at the Kendal power station in South Africa.

More

Differential Pressure (DP) Flow Yokogawa America

Differential Pressure Flow Meters consist of a Primary Element, a Secondary Element, and sometimes Tertiary Elements. Primary Element: The Primary Element generates the differential pressure in the fluid.

More

A Demonstration Study on a High Performance Vertical Roller Mill

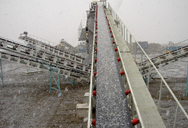

2012年2月28日 A series of tests using a pilot scale mill showed that these technologies reduce the fraction of coarse particles, power consumption of the mill and mill differential pressure. For an industrial scale-up, we conducted a demonstration test using a vertical roller mill equipped in a 700MW thermal power plant consisting of a pulverized coal firing ...

More

MillMaster—Technical - KIMA Process

pressure if the mill is under normal operation. Each time a limit is violated the fast decrease action will decrease the fresh feed and the roller pressure. inputs (actual values) mill vibration mill differential pressure main drive power main drive temperature torque signal roller pressure inputs (limits) mill vibration differential pressure

More

Modeling and Control of Coal Mill - ScienceDirect

2013年12月1日 The raw data was collected during mill start-up time, under the following operating conditions: Mass flow rate of raw coal -30 tons/hr; Mill differential pressure- 160200 mm wc; Primary air temperature- 250-280 ; Outlet temperature- 60-70 Motor current- 44A; Primary air flow56 tons/hr. Fig 4 to 7 represents the primary data used as input.

More

Dynamic classifiers: a fine way to help achieve lower emissions

2004年4月7日 Analysis of the results shows the mill pressure differential and the mill power consumption are a little higher with the dynamic classifier fitted. A significant fraction of the increases measured is due to the harder coal being ground, 49 v 52 HGI, during the post conversion guarantee test at a nominal coal flow of 36 t/h.

More

Reduced Unit Capacity

The differential pressure across the bowl (“bowl DP”) is an indication of flow restrictions through the mill. Bowl differential is the combined draft loss across the vane wheel and the coal retained above the bowl. Bowl

More

Melexis Pressure sensor ICs I Melexis

The MLX90824 is a packaged PCB-less, factory calibrated, absolute pressure sensor IC with a SENT output. It measures pressure spans from 1 to 4 bars. A pre-calibrated NTC thermistor input is available. Visit

More

(PDF) Performance Evaluation of Vertical Roller Mill

2017年9月11日 Samples were collected from mill inside and around the circuit to evaluate the performance of each operation in the system, individually. Particle size distributions of collected samples were...

More

Differential Pressure Sensors Setra Systems

Setra’s pressure sensors are considered best-in-class for a handful of reasons, including their accuracy, ranges, and stability. Setra produces sensors with accuracy as high as +/- 0.02% Full Scale. The sensors

More

Coal Hang-up in Bowl Mill Operations - Bright Hub Engineering

2009年9月11日 The boiler fuel input coming down due to coal flow hang-up the mill slowly gets unloaded. This can be inferred from the response of the boiler. Mill differential pressure comes down. Mill outlet temperature will rise. Boiler steam pressure will start falling. No coal flow alarm will appear. Coal feeder and mill will trip after some time.

More

Roller mills: Precisely reducing particle size with greater

The mill is suited to reducing fri-able or fragile and breakable materials — that is, any material that breaks rather than flattens under pressure — ... called the roll speed ratio (or roll speed differential). For instance, if one roll rotates at 1,000 rpm and the other at

More